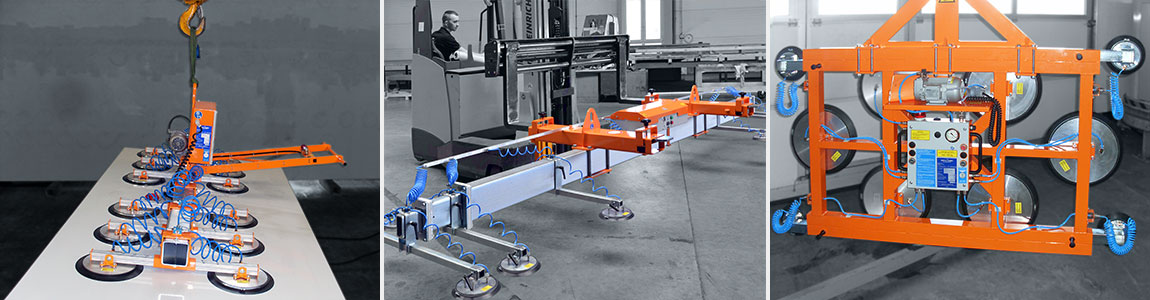

Sheet metal / Metal / Wood

Safety features

- Compliance with all criteria of DIN EN 13155

- Devices for internal handling of glass according DIN EN 13035

- CE mark according to Machinery Directive 2006/42/EG

- Devices with dual-circuit vacuum systems for construction site use

- Each vacuum circuit with 2-fold safety

- Integrated vacuum gauges

- Optical and/or acoustic warning devices signaling deviations from the nominal condition

- Pressure controlled vacuum to reduce the consumption of energy and compressed air

- Integrated pressure switch control to indicate malfunctions

- Construction site devices with 24 V battery systems with considerably increased safety compared to 12 V systems

- Battery devices with built-in battery level indicator

- Vacuum reservoir to compensate vacuum loss

- Energy-self-sufficient indicator to signal breakdown of energy supply

Legend

Crane attachment

Crane attachment Fork lift attachment

Fork lift attachment Handling horizontally

Handling horizontally Handling vertically

Handling vertically Rotate 360°

Rotate 360° Rotate +/- 90°

Rotate +/- 90° Rotate 90°/95°

Rotate 90°/95° Turn-over ≥ 180°

Turn-over ≥ 180° Turn-over 0 - 96°/98°

Turn-over 0 - 96°/98° Tilt around horizontal axis

Tilt around horizontal axis Incline 82°/84° - 90°

Incline 82°/84° - 90° Control panel at the device / cable remote control

Control panel at the device / cable remote control Radio remote control

Radio remote control Manual operation

Manual operation Mains current

Mains current Battery

Battery Compressed air

Compressed air