The vacuum based lifting and handling devices of the OKTOPUS® GLASS-Jack and OKTOPUS® GL-M product lines are vacuum lifting tools designed specifically for the assembly of glass elements on construction sites.

The vacuum is generated by a 24V battery system, with two batteries integrated into a dual-circuit or multi-circuit vacuum system. Therefore, depending on the lifting device and with maximum work safety ensured, even extremely heavy glass plates and extensive glass facade elements can be transported, lifted and assembled.

We offer the OKTOPUS® glass lifter as an attachment that can be handled flexibly as a chain- or wire rope hoist on construction site- or truck-mounted cranes. The device can also be purchased as a rigid construction to be used on mini cranes, telescopic handlers or forklift trucks.

Manually, electro-mechanically or hydraulically driven movements like jointing, tilting, tipping or turning not only ensure the precise positioning of glass plates, but also enable difficult and challenging glazing tasks like the assembly between facades and scaffoldings, or the overhead glass installation and under roof edges.

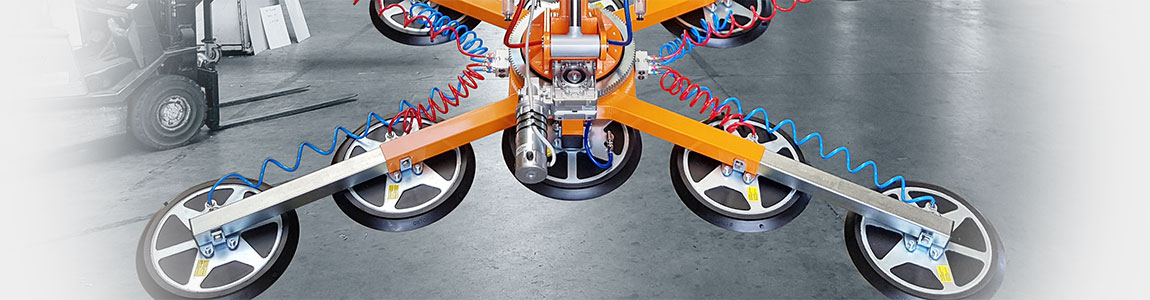

Depending on the version, the suction frame of the OKTOPUS® glass lifters can be purchased with pull-out or pluggable extensions, with adapters for concavely or convexly curved glass plates, or as a suction device with movable crossbeams.

Other options of the vacuum based lifting and handling devices are, for example:

- Blow-off function

- Spring loaded suction device

- Height-adjustable crane attachment with tilt-adjustable clamping lever

- Hydraulic lowering cylinder for a smooth, jolt-free and safe discharge of sucked plates

- Counterweight balancers for heavy glass elements

- Cable- or transmitter radio remote control

- Stop-cocks

- Pluggable cable remote controls

Devices for flat glass panes >>

Devices for curved glass panes >>

Devices with integrated CWB >>

Construction site manipulators for glass >>

Variable counterweight balancers for glass pane installation >>