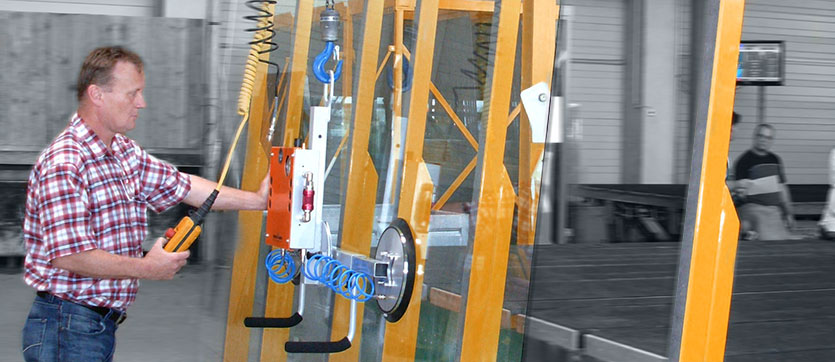

The vacuum lifters of the ERGO-Sprint series are especially designed for shop floor transport and handling in combination with indoor cranes, X-Y lightweight cranes or column and wall-mounted slewing cranes. Special solutions allow handling the device with a forklift..

The series OKTOPUS® ERGO-Sprint is impresses with:

- the use in hoists with flexible guide (chain hoists or rope lashings for lifting or lowering the load) and horizontal rotation by 360° in the crane hook

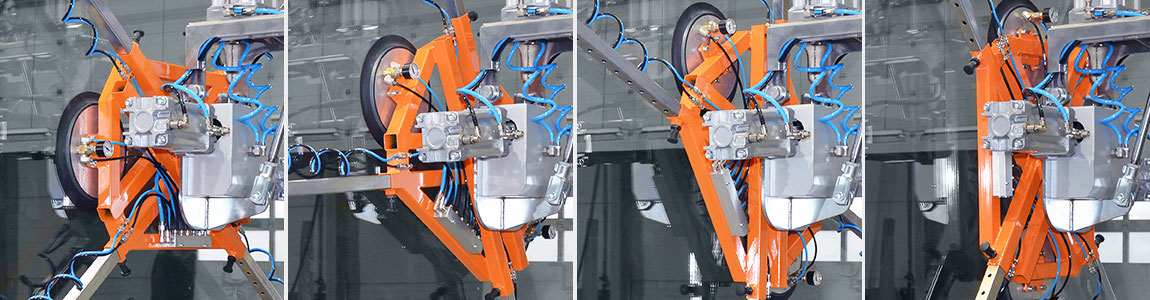

- the availability of manual, electrical, hydraulic and pneumatic positioning facilities (rotating, tilting)

- a variety of suction frame versions for perfect adjustment to payloads and pane shapes; special solutions for curved panes as well

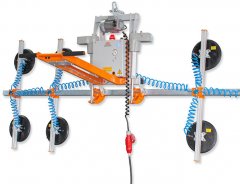

- telescopic extension arms for tool-free adjustment of the suction bridge shape to the loads to be manipulated

- the option to adjust and combine available energy sources (compressed air, 400 V, 230 V or 24 V with battery use) for vacuum generation and positioning the loads

- the option of pneumatically operated devices to equip each suction pad with separate vacuum generation (ejectors) with non-return valve and vacuum gauge

- the expansive safety facilities (depending on the equipment)

- compressed-air or vacuum gauge

- optical and/or acoustical signaling devices to monitor power supply and vacuum function

- central or decentral arranged non-return valves

- charge level indicator

- minimum requirements for maintenance and preventive service

- the following options: blow-off functions, automatic energy saving function, spring-mounted suction pads, adjustable crane mounting, cable and radio remote control for electrical devices, chain hoists, manually, electrically or pneumatically height-adjustable control panel

-

Working Load Limit: 150 / 250 / 350 / 500 / 1000 kg

special solutions up to 6500 kg and for curved panesSuction frame: X-shaped or rectangular with telescopic extensions or as spreader beam with shifting cross beams Vacuum generation: by ejectors (with/without automatic energy saving function) with non-return valve or by electrical vacuum pumps Power supply: compressed air: 6-9 bar quick coupling 1/4“, 1/2“, 3/8“

power supply: 400 V, 230 V, 24 V battery systemSafety facilities: in the compressed-air area gauge and emergency whistle, vacuum gauge on each suction pad Color: suction frame RAL 2011 deep orange Movements Lifting/Lowering: with chain hoist or rope lashing or with forklift (each provided by the customer) Rotating horizontally: in the crane hook, manually 360°

ERGO-Sprint: suction frame versions

OKTOPUS® ERGO-Sprint 150/250/350 A/B

-

Type suction frame: small design, X-shaped or rectangular with telescopic extensions max. glass dimensions: depending on the suction frame shape and glass thickness Working Load Limit: depending on the type 150/250/350 kg, others on request Suction frame movements Rotating - 0 - 90°, manually/pneumatically/electrically

- +/- 90°, manually

- 360°, manually/electricallyTilting 0 - 90°, manually/pneumatically/electrically

ERGO-Sprint 150/250/350 A/B example

ERGO-Sprint 250 D A 600 S TA CA EZG

index.php?option=com_content&view=article&id=409&Itemid=1164

ERGO-Sprint 250 DS A 160 S M CA EZG

index.php?option=com_content&view=article&id=407&Itemid=1165

ERGO-Sprint 350 D B 700 S M AC3 P

index.php?option=com_content&view=article&id=408&Itemid=1166

ERGO-Sprint 350 D B 100 S M CA EZU

index.php?option=com_content&view=article&id=413&Itemid=1156

ERGO-Sprint 250 DS A 570 S E AC3-24 P

index.php?option=com_content&view=article&id=414&Itemid=1157

ERGO-Sprint 250 D B 100 S M CA EZU

index.php?option=com_content&view=article&id=415&Itemid=1158

ERGO-Sprint 150/250/350/500/1000 S T

-

Type suction frame: spreader beam consisting of one main girder and at least two shifting cross beams max. glass dimensions: depending on the suction frame shape and glass thickness; suitable for long, narrow panes Working Load Limit: depending on the type 150/250/350/500/1000 kg Suction frame movements Rotating - 0 - 90°, manually/pneumatically/electrically

- +/- 90°, manually

- 360°, manually/electricallyTilting 0 - 90°, manually/pneumatically/electrically

ERGO-Sprint 150/250/350/500/1000 T example

ERGO Sprint 250 S T

index.php?option=com_content&view=article&id=529&Itemid=1167

ERGO Sprint 350 S T

index.php?option=com_content&view=article&id=530&Itemid=1168

ERGO Sprint 500 S T

index.php?option=com_content&view=article&id=531&Itemid=1169

ERGO-Sprint 350 DS T 570 SE AC3 24P

index.php?option=com_content&view=article&id=532&Itemid=1159

ERGO-Sprint 150/250/350/500/1000 X/Q

-

Type suction frame: large design, X-shaped or rectangular with telescopic extensions,

special frames for curved panesmax. glass dimensions: depending on the suction frame shape and glass thickness Working Load Limit: depending on the type 150/250/350/500/1000 kg, special solutions up to 6500 kg and for curved panes Suction frame movements Rotating - 0 - 90°, manually/pneumatically/electrically

- +/- 90°, manually

- 360°, manually/electricallyTilting 0 - 90°, manually/pneumatically/electrically

ERGO-Sprint 150/250/350/500/1000 X/Q example

ERGO-Sprint 500 DES X 770 S M B24-P

index.php?option=com_content&view=article&id=412&Itemid=1160

ERGO-Sprint 500 DES X 570 S EA B24-P

index.php?option=com_content&view=article&id=410&Itemid=1163

ERGO-Sprint 1000 S X 030 S EA AC3 24 P

index.php?option=com_content&view=article&id=411&Itemid=1161

ERGO-Sprint 500 DES Q 570 S EA AC1 B24 P

index.php?option=com_content&view=article&id=528&Itemid=1162