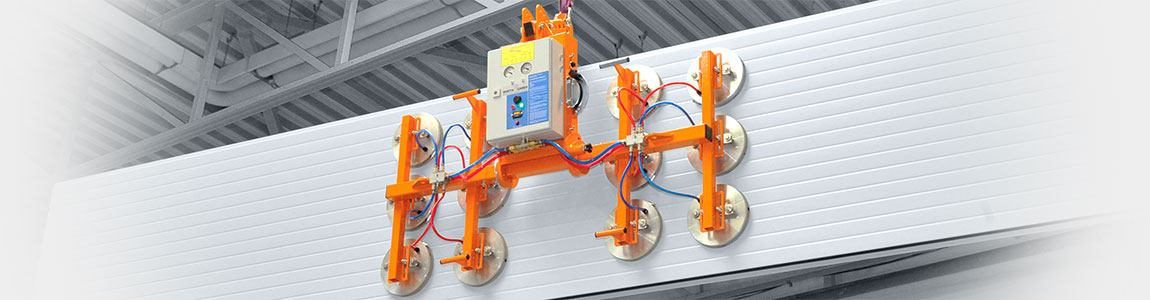

Installation of sandwich elements

Safety features

- Compliance with all criteria of DIN EN 13155

- Devices for internal handling of glass according DIN EN 13035

- CE mark according to Machinery Directive 2006/42/EG

- Devices with dual-circuit vacuum systems for construction site use

- Each vacuum circuit with 2-fold safety

- Integrated vacuum gauges

- Optical and/or acoustic warning devices signaling deviations from the nominal condition

- Pressure controlled vacuum to reduce the consumption of energy and compressed air

- Integrated pressure switch control to indicate malfunctions

- Construction site devices with 24 V battery systems with considerably increased safety compared to 12 V systems

- Battery devices with built-in battery level indicator

- Vacuum reservoir to compensate vacuum loss

- Energy-self-sufficient indicator to signal breakdown of energy supply

Legend

Crane attachment

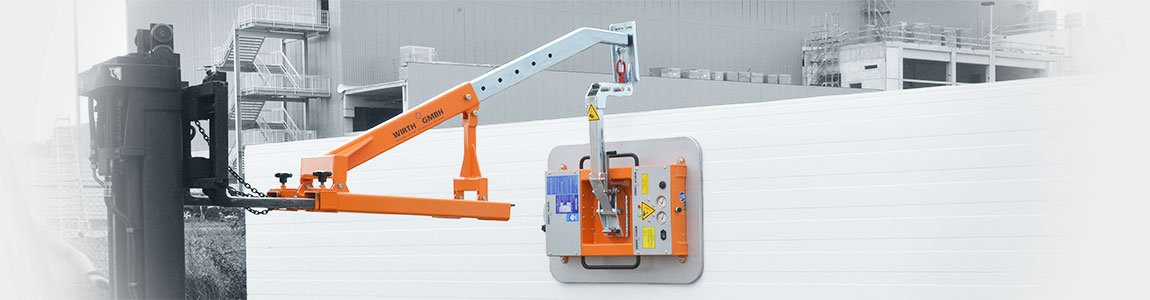

Crane attachment Fork lift attachment

Fork lift attachment Vertical wall installation

Vertical wall installation Horizontal wall installation

Horizontal wall installation Roof installation

Roof installation Overhead installation

Overhead installation Rotate 360°

Rotate 360° Tilt around horizontal axis

Tilt around horizontal axis Turn-over ≥ 180°

Turn-over ≥ 180° Tilt around vertical axis (swivel)

Tilt around vertical axis (swivel) Side stroke

Side stroke Teleskop. Ausleger/ Kranarm/Hubsäule

Teleskop. Ausleger/ Kranarm/Hubsäule Control panel at the device / cable remote control

Control panel at the device / cable remote control Radio remote control

Radio remote control Manual operation

Manual operation Battery

Battery