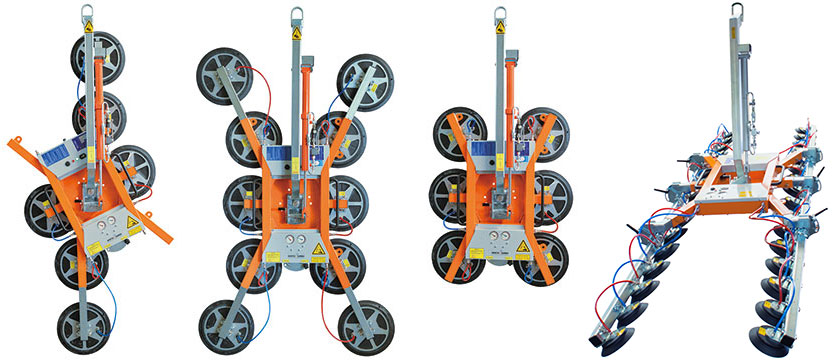

Vacuum lifter for construction site use with manual rotating and tilting function

Dual-circuit system

for construction site use according to DIN EN 13155

Use

Handling flat glass, concave or convex curved glass panes with bending radius ≥ 2 m (only together with optional available suction pad adapter for curved glass panes) and window elements on construction sites. The suction areas of the elements to be lifted must be air-impermeable, have to have an even and clean surface and must not be covered with protective foil.

Hoist

truck-mounted crane, mini crane

Fastening

at the crane hook

Description

Extension arms allow handling large-sized elements up to a maximum weight of 1000 kg. The optional available lowering cylinder allows a smooth and jerkless lowering of the load. The also optional available blow-off function eases and quickens release of the suctioned glass panes.

In order to manipulate curved glass panes with the OKTOPUS® GLASS-Jack GL-KN 1000 as well, we developed a special suction pad adapter. It allows manipulating convex or concave curved glass panes with a radius of at least 2000 mm. With a total of 16 suction pads the suction pad adapter can securely lift and transport loads of up to 800 kg. The total weight of the OKTOPUS® GLASS-Jack GL-KN 1000 with mounted adapter for curved glass panes amounts to 180 kg. Deviations from the nominal condition are indicated by optical and acoustical warning devices. Even in the case of complete energy breakdown the vacuum remains in each suction pad for at least 5 minutes. In this way a secure lowering of the load can be ensured at all times.

-

Device / Suction pads maximum Working Load Limit 10 suction pads ∅ 400 mm up to 1000 kg (flat glass panes) 16 suction pads ∅ 280 mm up to 800 kg (flat glass panes and curved glass panes)

-

Weight depending on the equipment ca. 90 kg - 180 kg Suction pads 10 pcs. Ø 400 mm and 16 pcs. Ø 280 mm Vacuum generation electrical vacuum pump Operation operating lever on the device Vacuum system dual-circuit system for construction site use Nominal pressure pneumatic system -0,65 bar to -0,73 bar Power supply 24 V DC battery system Optional facilities - crane arm with hydraulic lowering cylinder

- blow-off function

- cable remote control

- radio remote control

- preparation of the basic device to operate a counterweight balancerOptional equipment - adapter for handling curved glass panes (R => 2.000 mm)

- transport cart, large with forklift adapter

- transport cart small, two-pieceMovements Lifting and lowering by the crane hook Rotating horizontally in the crane hook, manually 360° Rotation suction frame manually 360°, lockable every 45° Tilting suction frame manually 0-90°

Use of OKTOPUS® GLASS-Jack GL-KN 1000

glass-jack gl-kn1000

OKTOPUS-GLASS-Jack_GL-KN1000_04.jpg

OKTOPUS-GLASS-Jack_GL-KN1000_05.jpg

OKTOPUS-GLASS-Jack_GL-KN1000_01.jpg

Datasheet OKTOPUS® Glass-Jack KN 1000

Datasheet OKTOPUS® Glass-Jack KN 1000