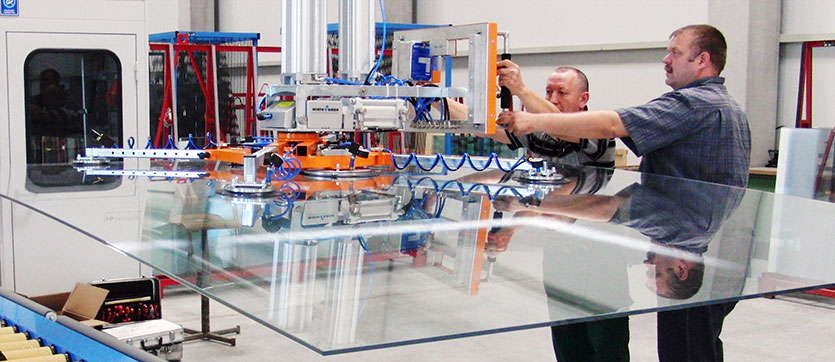

The ERGO-Jet is a pneumatically driven vacuum handling device for safe and ergonomic shop floor operation for glass processing or window production.

Die The series ERGO-Jet impresses with:

- a pneumatic stepless telescopic lifting column that can be rotated by 360° for precise positioning

- the use at double bridges of lightweight crane systems or double rail booms of column or wall-mounted slewing cranes

- the rigid connection between lifting column and crane runway by a double-rail crane trolley

- telescopic extension arms for tool-free adjustment of the suction bridge shape to the loads to be manipulated

- optionally available vacuum generation by controlled ejectors with non-return valves or built-in vacuum gauges

- the arrangement of operating elements that allow operating the ERGO-Jet and guiding it with the handles at the same time

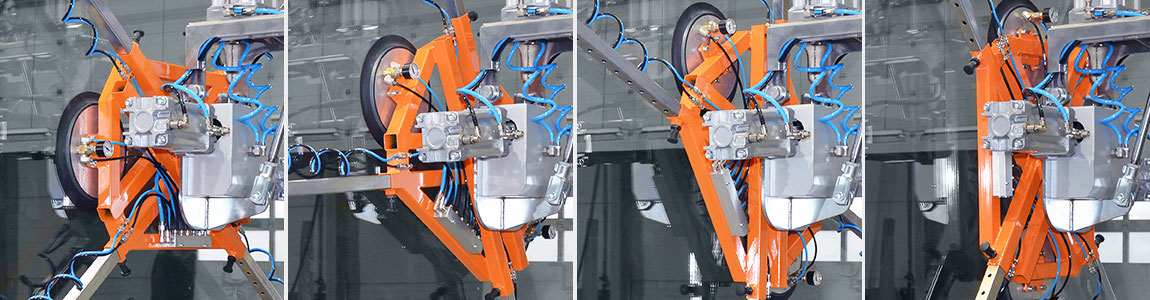

- very precisely adjustable positioning movements (depending on the device: rotating, tilting, inclination)

- reduced weight due to predominant use of aluminium and optimized lightweight profiles

- minimum requirements for maintenance and preventive servicing

- handling large and heavy glass panes by one operator only

- minimization of energy, time and costs

- the following options: blow-off function, automatic energy saving function, spring-mounted suction pads, decentralized vacuum generation, manually or pneumatically height-adjustable control panel

-

Working Load Limit: 150 / 250 / 350 / 500 kg Vacuum frame: 4 standard frames (diagonal, rectangular/ large, small),

special frames on request,

telescopic extensionsVacuum generation: ejectors (Venturi nozzles) with non-return valve and blow-off function,

energy saving function optionalPower supply: compressed air 6-9 bar, quick coupling NW9 Safety devices: in the compressed air area gauge and whistle,

vacuum gauges on each suction padColor: RAL 9006, white aluminium vacuum frame RAL 2011, deep orange

other colors on requestAdditional functions: - height-adjustable control panel

- depth-adjustable control panel

- pneumatic drive

- suction pad extensionsMovements Lifting / lowering: pneumatically stepless with telescopic lifting cylinder Rotating horizontally: in the lifting tube, manually 360°

OKTOPUS® ERGO Jet versions

ERGO-Jet 250 S X 060 S TA CA EDU

-

Working Load Limit: 250 kg Weight: approx. 135 kg Vacuum system: decentralized ejector with non-return valve and blow-off function on each suction pad Warning devices: vacuum/compressed air: gauge and whistle Power supply: compressed air 6-9 bar Color: RAL 9006/2011 Application: Loading/unloading vert./horiz. glass processing machines Movements Rotating: in the lifting column, manually 360° Lifting/Lowering: rigidly guided in the lifting column Tilting: basic frame 90°

ERGO-Jet 250 WN So 060 S TA CA EDU

-

Working Load Limit: 240 kg Weight: approx. 240 kg Vacuum system: decentralized ejector with non-return valve and blow-off function on each suction pad Warning devices: vacuum/compressed air: gauge and whistle Power supply: compressed air 6-9 bar Color: RAL 9006/2011 Application: handling coated glass elements,

processing the back side of glass panesMovements Rotating: in the lifting column, manually 360° Lifting/Lowering: rigidly guided in the lifting column Tilting: basic frame 90°