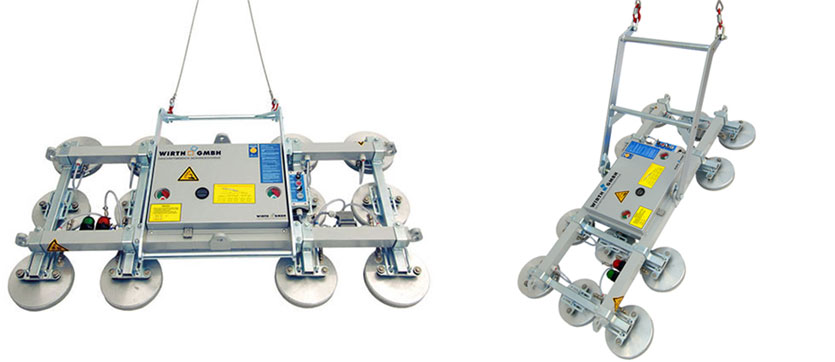

OKTOPUS® PANEL-Jack KT-B with 10 m roof cross beam

For the installation of horizontal and vertical wall elements as well as for installing roof elements

Dual circuit system

- 2 independent vacuum circuits, each vacuum circuit with 2-fold safety and integrated reserve vacuum

- for construction site use according to DIN EN 13155

Application

- The single device is suitable for horizontal and vertical installation of wall elements as well as the installation of roof elements with a maximum length of 8 m.

- In connection with a 5 m roof cross beam (DT5) it can be used to install roof elements with a maximum length of approx. 14 m.

- It is possible to couple two single OKTOPUS® PANEL-Jack KT-B with the help of a roof cross beam (DT6 or DT10) of either 6 m or 10 m in length. In this case you can install roof elements of up to 22 m in length.

Hoist

- e. g. truck-mounted crane, top slewing crane

Suspension

- crane mounting horizontal installation: is needed for horizontal wall installation,

- crane mounting vertical installation: is needed for vertical wall installation

- 6 m (DT6) or 10 m (DT10) in length with adjustable chain lashing

Equipment

- chain lashing

- rope lashing

- safety belts

Options

- set of spare batteries and additional battery box to double operating time

Material to be handled

Using the tried and tested Wirth round and oval suction pads you can transport and install almost every standard sandwich element and many corrugated sheets with the OKTOPUS® PANEL-Jack KT-B. The suction areas of the elements to be lifted must be air-impermeable, have to have an even and clean surface and must not be covered with protective film.

-

Combination of either the 6 m or the 10 m roof cross beam with: Max. working load limit depending on the type of suction pad and the inclination (α) of the elements to be installed

0° ≤ α ≤ 10°2 KT-B with 8 round suction pads (ø 250 mm) per device 600 kg 2 KT-B with 12 oval suction pads (100 mm x 320 mm) per device 600 kg

-

Weight: two single devices including DT6/10: approx. 350 kg Operation: control panel centrally mounted on the DT6 and DT10 Power supply: rechargeable battery, 24 V Vacuum generation: vacuum pump Suction pads: Wirth standard suction pads

- round suction pads (ø 250 mm) or

oval suction pads (100 mm x 320 mm)Equipment: - crane mounting horizontal installation

- crane mounting vertical installation

- chain lashing (2 chains, 2 ropes, l = 7 m) for DT6 and DT10

- transport box for single devices

- transport palette

- safety belts

- protective caps for suction padsOptions: set of spare batteries

Use of OKTOPUS® PANEL-Jack KT-B with crossbeam 10 m

panel-jack kt-b dt 10

OKTOPUS-PANEL-Jack_KT-B_DT10_02.jpg

OKTOPUS-PANEL-Jack_KT-B_DT10_03.jpg

OKTOPUS-PANEL-Jack_KT-B_DT10_04.jpg

OKTOPUS-PANEL-Jack_KT-B_DT10_01.jpg

Datasheet PANEL-Jack KT-B with crossbeam 10 m

Datasheet PANEL-Jack KT-B with crossbeam 10 m