Manipulator for handling large-sized flat and curved glass elements in difficult to access areas (facade openings, eaves)

Dual-circuit system

- 2 independent vacuum circuits, each vacuum circuit with 2-fold safety and integrated vacuum reservoir

- for construction site use according to DIN EN 13155

Use

Handling flat and curved glass panes (concave or convex, bending radius ≥ 1.6 m) in difficult to access areas (façade openings, eaves). The suction areas of the elements to be lifted must be air-impermeable, have to have an even and clean surface and must not be covered with protective foil.

Hoist

- crane

Fastening

- at the crane hook

Description

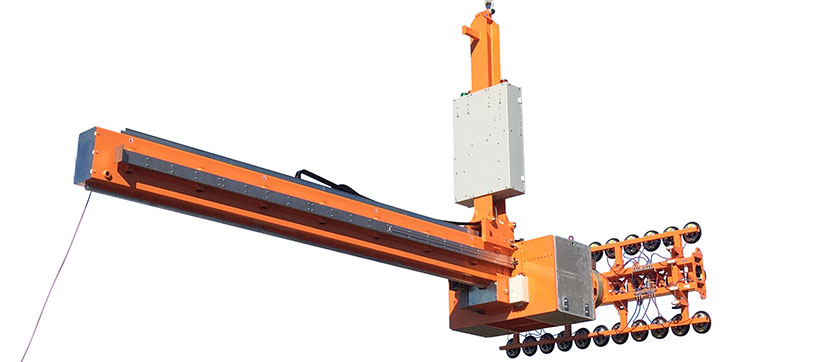

The vacuum based load lifting attachment OKTOPUS® GL-MGS 4600 GGA is designed to handle large-sized glass panes and window elements with a maximum weight of up to 4600 kg. It is equipped with a dual-circuit vacuum system for construction site use according to DIN EN 13155. The crane eye of the device allows attaching the device to an existing hoist (provided by the customer). Furthermore, the load can be balanced by an integrated movable counterweight balancer. The overhang reaching from the suction frame to the crane mounting can be adjusted (range: 2 m to 5.7 m) with the help of a hand crank. The suction frame can hydraulically be rotated endless by 360°, tilted by -45° to +10°and swiveled by ±20°. The operating and display elements are arranged ergonomically and allow comfortably positioning and moving the load. The electrically operated vacuum pump is supplied with energy by a 24 V DC battery system. Deviations from the nominal condition are indicated by optical and acoustical warning devices. Even in the case of complete energy breakdown, vacuum remains in each suction pad for at least 5 minutes. In this way a secure lowering of the load can be ensured at all times.

Material to be handled

The OKTOPUS® GL-MGS 4600 is suitable for handling flat glass panes, curved glass panes (concave or convex, bending radius ≥ 1.6 m) and window elements. The suction areas of the elements to be lifted must be air-impermeable, have to have an even and clean surface and must not be covered with protective film.

-

Device / Suction pads maximum Working Load Limit 32 suction pads ∅ 280 mm up to 1,600 kg 56 suction pads ∅ 280 mm up to 2,800 kg 68 suction pads ∅ 280 mm up to 3,400 kg 92 suction pads ∅ 280 mm up to 4,600 kg

-

Weight approx. 10,500 kg including 24 counterweights Suction pads 92 pcs. Ø 280 mm Suction frame versions including 24 counterweights

version 1: 3.3 m x 1.4 m with up to 32 suction pads, Working Load Limit 1600 kg

version 2: 5.7 m x 1.4 m with up to 56 suction pads, Working Load Limit 2800 kg

version 3: 6.9 m x 1.4 m with up to 68 suction pads, Working Load Limit 3400 kg

version 4: 9.3 m x 1.4 m with up to 92 suction pads, Working Load Limit 4600 kgOverhang up to the crane mounting adjustable between 2 m and 5.7 m Counterweights 20 pieces removable (1 counterweight = 240 kg)

1 piece traveling cage (1000 kg)Vacuum generation electrical vacuum pump, non-return valve Operation cabel remote control (2.4 GHz) Vacuum system dual-circuit system for construction site use,

blow-off function for quicker air supply of the suction padsPower supply 24 V battery system Optional equipment - technical documentation (German/English)

- built-in battery charger

- transport rackMovements Lifting and lowering by the crane hook Rotating horizontally in the crane hook, manually 360° Rotation of the suction bridge hydraulically 360° endless Tilting the suction bridge hydraulically -45° to +10° Swiveling the suction bridge hydraulically ±20°

Use of OKTOPUS® GL-MGS 4600

glas gl-mgs 4600

gl-mgs4600_02.jpg

gl-mgs4600_03.jpg

gl-mgs4600_04.jpg

gl-mgs4600_01.jpg