The product family OKTOPUS® ERGO-Lift completes the range of rigidly guided handling devices for loads up to 1,100 kg. ERGO-Lift handling devices are applied in X-Y lightweight crane systems. The use of electric motors allows rotating the suctioned elements endless by 360°.

The series ERGO-Lift impresses with:

- Working Load Limits up to 1,100 kg

- the pneumatic electric stepless telescopic lifting column that can be rotated by 360° for precise positioning

- the use at double bridges of lightweight crane systems or double rail booms of column or wall-mounted slewing cranes

- the rigid connection between lifting column and crane way by the double-rail crane trolley

- telescopic extension arms for tool-free adjustment of the suction bridge shape to the loads to be manipulated

- vacuum generation by either controlled/uncontrolled ejectors or by electrical vacuum pumps (230/400 V)

- the arrangement of the operating elements that allow operating the ERGO-Jet and guiding the device with the handles at the same time

- the very precisely adjustable positioning movements (depending on the equipment: rotating, tilting, inclination)

- minimum requirements for maintenance and preservative service

- handling large and heavy glass panes by one operator only

- minimization of energy, time and costs

- the following options: blow-off function, automatic energy saving function, spring-mounted suction pads, decentralized vacuum generation, pneumatic or electric height-adjustable control panel

-

Working Load Limit: 150 / 250 / 350 / 500 / 1,100 kg

special solutions up to 6500 kg and for curved glass panesVacuum frame: X-shaped or rectangular, with telescopic extensions Vacuum generation: 2 pcs. Ø 200 mm (telescopic, pluggable),

2 pcs. Ø 290mm (telescopic)Vacuum generation: ejectors with non-return valve, with/without energy saving function or electrical vacuum pumps Power supply: compressed air 6-9 bar

power supply: 400V, 230V

quick couplings 1/4“,1/2“, 3/8“Color: RAL 9006, white aluminium RAL 2011, deep orange Movements Lifting/Lowering: with chain hoist or rope lashing, or with forklift (each provided by the customer) Rotating horizontally: in the crane hook, manually 360° Rotation: vacuum frame 90° / 360°, electrically Inclination: vacuum frame 82° / 84°- 90°, pneumatically / electrically Tilting: vacuum frame 0°- 82° / 90°, pneumatically / electrically

Depending on the application it is also possible to use different energy sources (compressed-air, 400 V, 230 V) and combine these for vacuum generation and positioning the loads.

OKTOPUS® ERGO-Lift Versions

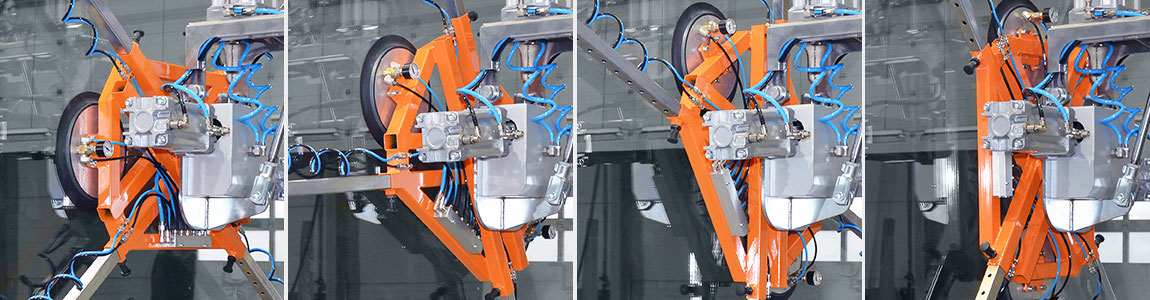

OKTOPUS® ERGO-Lift 600 DES 560 S TA EZU

-

Working Load Limit: 600 kg Weight: ca. 330 kg Suction frame type: X-frame Hoist: chain hoist integrated Suction pads: 8 pcs. Ø 300 mm

(4 pcs. extendable, pluggable)Vacuum generation: central ejector with non-return valve and blow-off function Power supply: compressed air 6-9 bar

mains grid 400 VColor: RAL 9006/2011 Application: loading/unloading vert./horiz. glass processing machines Movements Lifting/Lowering: rigidly guided tubular construction with chain hoist inside, stepless operation by the operator Rotating horizontally: in the trolley frame, manually 360° Stroke: 1200 mm standard, other lengths on request (stroke dimensioning) Rotating: suction frame 360° endless, electrically Tilting: suction frame 0-90°, pneumatically

OKTOPUS® ERGO-Lift 1100 DS X 730 S TA CA EZU

-

Working Load Limit: 1100 kg Weight: ca. 330 kg Suction frame: including installation supports for insulated glass Suction pads: 6 pcs. Ø 400 mm

(4 pcs. extendable, pluggable)Vacuum generation: central ejector with non-return valve and blow-off function Power supply: compressed air 6-9 bar

mains grid 400 VColor: compressed air 6-9 bar

mains grid 400 VColor: lifting tube frame RAL 9006, white aluminium,

suction frame RAL 2011, deep orangeMovements Lifting/Lowering: rigidly guided tubular construction with chain hoist inside,

stepless operation by the operatorRotating horizontally: in the trolley frame, manually 360° Stroke: 1200 mm standard, other lengths on request (stroke dimensioning) Rotating: suction frame 0-90°, electrically Tilting: suction frame 0-90°, hydraulically