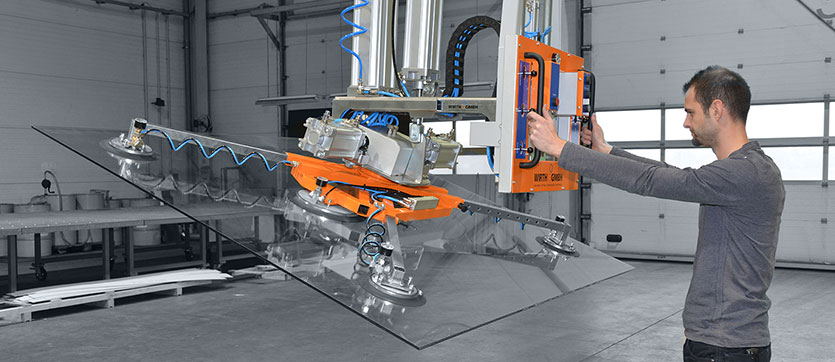

The OKTOPUS® ERGO-Pick is a very economic, light weight and extra quick pneumatically operated vacuum lifter. It can be mounted to a single rail crane system, it does not need a chain hoist and its advantages are controlled load handling in a pneumatic lifting cylinder and immediate vacuum generation (central ejector) upon glass contact.

The series ERGO-Pick impresses with:

- the application in lightweight crane systems or column/wall-mounted slewing cranes

- the built-in pneumatic lifting cylinder and by that economization of costly and high-maintenance chain hoists

- horizontal rotation by 360° in the carriage adapter

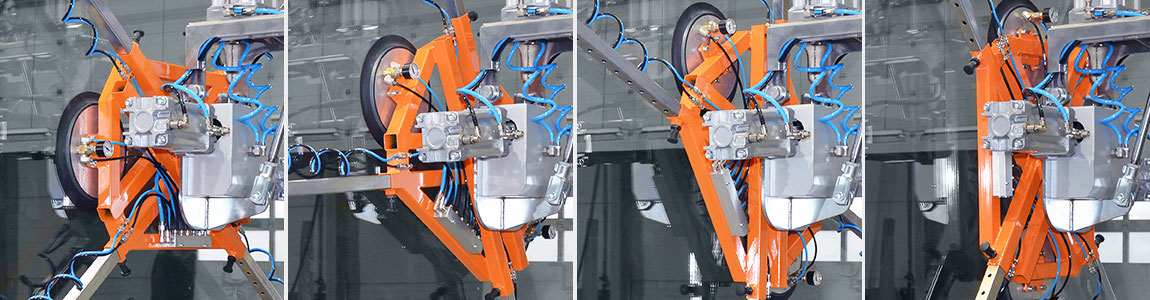

- availability of manual and/or pneumatic positioning facilities (rotating, tilting the load)

- a variety of suction frame versions for optimum adjustments to payloads and pane shapes

- telescopic extension arms for tool-free adjustment of the suction bridge shape to the loads to be manipulated

- the option of pneumatically operated devices to equip each suction pad with its own vacuum generation (ejectors) with non-return valve and vacuum gauge

- the expansive safety facilities (depending on the equipment)

- compressed-air or vacuum gauge

- acoustical signaling devices to monitor energy supply or vacuum function

- central or decentral arranged non-return valves

- minimum requirements for maintenance and preventive service

- the following options: blow-off function, automatic energy saving function, spring-mounted suction pads, decentralized vacuum generation, manually or pneumatically height-adjustable control panel

-

max. glass dimensions: depending on the shape of the suction frame and glass thickness, up to 2,600 x 3,210 mm recommended Working Load Limit: 150 / 250 / 350 / 500 kg Vacuum frame: X-shaped or rectangular, with telescopic extensions Vacuum generation: ejectors with non-return valves, with / without energy saving function Power supply: compressed air 6-9 bar, quick couplings 1/4“,1/2“, 3/8“ Color: RAL 9006, white aluminium vacuum frame RAL 2011, deep orange Movements Lifting/Lowering: pneumatic stepless by telescopic lifting cylinder Rotating device: in the carriage adapter, manually 360°

The OKTOPUS® ERGO-Pick is the perfect device for optimizing production processes with low effort in flat glass manufacturing and processing companies or window production and for reducing costs significantly.

OKTOPUS® ERGO-Pick versions

OKTOPUS® ERGO-Pick 250 D R 600 S TA CAU

-

Working Load Limit: 250 kg Weight: approx. 800 kg Suction pads: 2 pcs. Ø 200 mm (telescopic, pluggable),

2 pcs. Ø 290mm (telescopic)Vacuum generation: central ejector with blow-off function Power supply: compressed air: 6-9 bar 3/4“ Color: lifting column aluminium unpainted

suction frame RAL 2011 deep orangeMovements Lifting/Lowering: Pneumatic cylinder, pneumatically, stepless operation by operator Rotating horizontally: manually 360° Stroke: 1200 mm standard, other lengths on request Movements suction frame: rotating pneumatically, 0-90°

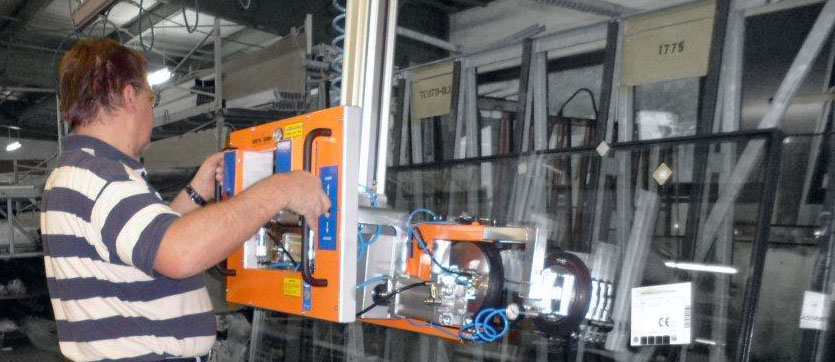

OKTOPUS® ERGO-Pick 350 DN R 660 S TA CA EZU

-

Working Load Limit: 350 kg Weight: ca. 110 kg Suction pads: 2 pcs. Ø 290 mm

4 pcs. Ø 200 mm (4 pcs. telescopic, pluggable)Vacuum generation: central ejector with blow-off function Power supply: compressed air: 6-9 bar 3/4“ Color: suction frame RAL 2011 deep orange Movements Lifting/Lowering: Pneumatic cylinder, pneumatic, stepless operation by the operator Rotating horizontally: manually 360° Stroke: 1200 mm standard, other lengths on request (stroke dimensioning) Movements suction frame: rotating pneumatically, 0-90°

tilting pneumatically, 0-90°